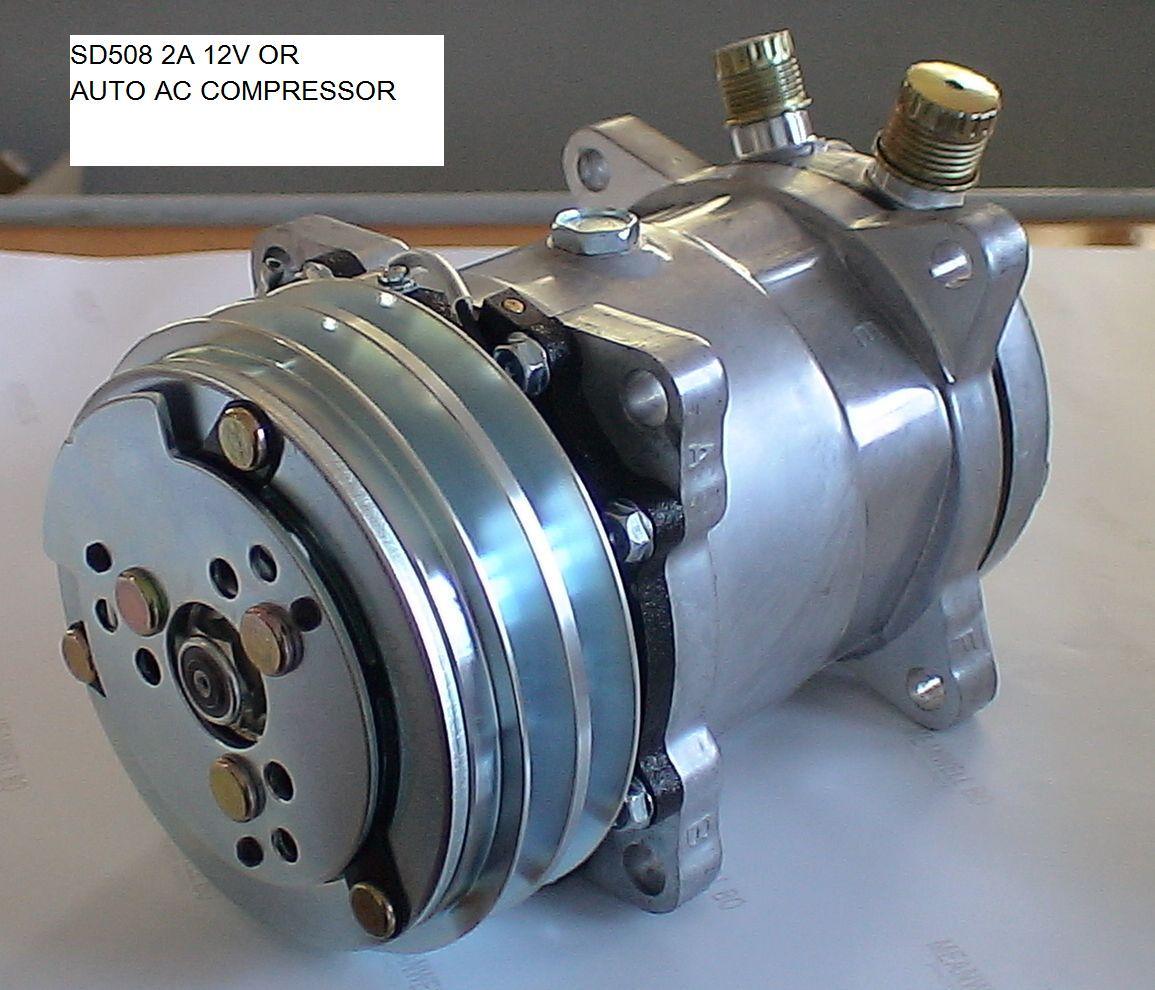

To operate correctly, the AC condenser needs a steady flow of air through its fins. Compressors generally are not serviceable and are an expensive The compressor can overheat and damage itself by trying to run with too little refrigerant in the system. Not only will a system leak stop the AC system from cooling, it can damage the compressor. Identify the leak, replace the faulty component, and then evacuate and recharge the system. If a leak is present in any component, simply recharging the system with new refrigerant will be at best a temporary fix. Anything that allows refrigerant to escape or contaminants to enter can cause a failure. Absorbs heat when air blows across evaporator, it is cool and dryīelow is an AC system diagram that shows the main components used and how they’re connected:īecause automotive air-conditioning systems operate under pressure, they need to remain completely sealed from the surrounding environment.Refrigerant converts back to gaseous state in the evaporator.Expansion valve reduces refrigerant pressure.Receiver/dryer removes water from refrigerant.Refrigerant cools and converts to liquid in the condenser.High-temperature/high-pressure refrigerant leaves the compressor (gas).Low-temperature/low-pressure refrigerant enters the compressor (gas).Only component mounted inside passenger compartment, behind dashboard.Cabin air is cooled and dried as it blows across the evaporator.Refrigerant changes back to gaseous state in the evaporator, causing a cooling effect.Mounted on high-pressure side of system, between dryer and firewall.Refrigerant is still in liquid form after leaving metering device.Lowers refrigerant pressure, which quickly drops refrigerant temperature.Either expansion valve or fixed orifice tube.Mounted on high-pressure side of system, between condenser and metering device.Removes water from the refrigerant using a desiccant (drying agent).Mounted in front of vehicle, behind grill.Similar to the engine radiator, it uses forced air (fan or vehicle movement) to transfer heat.Refrigerant changes from gaseous state to liquid state as it cools.Reduces temperature of refrigerant while it maintains high pressure.Mounted to front of engine and driven by serpentine belt.Takes in low-pressure gas and compresses it into high-temperature/high-pressure gas.Power unit of the system that separates the low-pressure side from the high-pressure side.Listed below are the main parts and their roles: Compressor

Car AC System PartsĪutomotive air-conditioning systems have a few key components.

The newest refrigerant is R-1234yf, which produces fewer greenhouse gases.Įurope requires the use of R-1234yf, and it will likely be the new standard in the United States in the near future. R-134a is an HFC-based (hydrofluorocarbon) refrigerant that does not have the ozone destroying properties of R-12/Freon. Manufacturers transitioned to R-134a in the mid-1990s. That widespread usage of R-12 was damaging the earth’s ozone layer. During the late 1980s, scientists discovered R-12 (aka Freon) is a very effective CFC-based (chlorofluorocarbon) refrigerant that is not flammable and not poisonous to humans. In the past, automotive air condition systems used R-12 as the refrigerant. To change the refrigerant between a liquid and a gaseous state, the air-conditioning system works to control pressure and temperature. As the refrigerant changes states, it absorbs heat and humidity from the vehicle and allows the system to give off cool, dry air. The air-conditioning system in a car works by manipulating refrigerant between a liquid and a gaseous state. Who has always been curious about how car AC works, continue reading below for a deeper look into air-conditioner theory, system components and system operation. When asked how car air conditioning systems work, most people would respond, “I don’t care how they work, I just want them to work!” While that may be a common response, it does not answer the question.

0 kommentar(er)

0 kommentar(er)